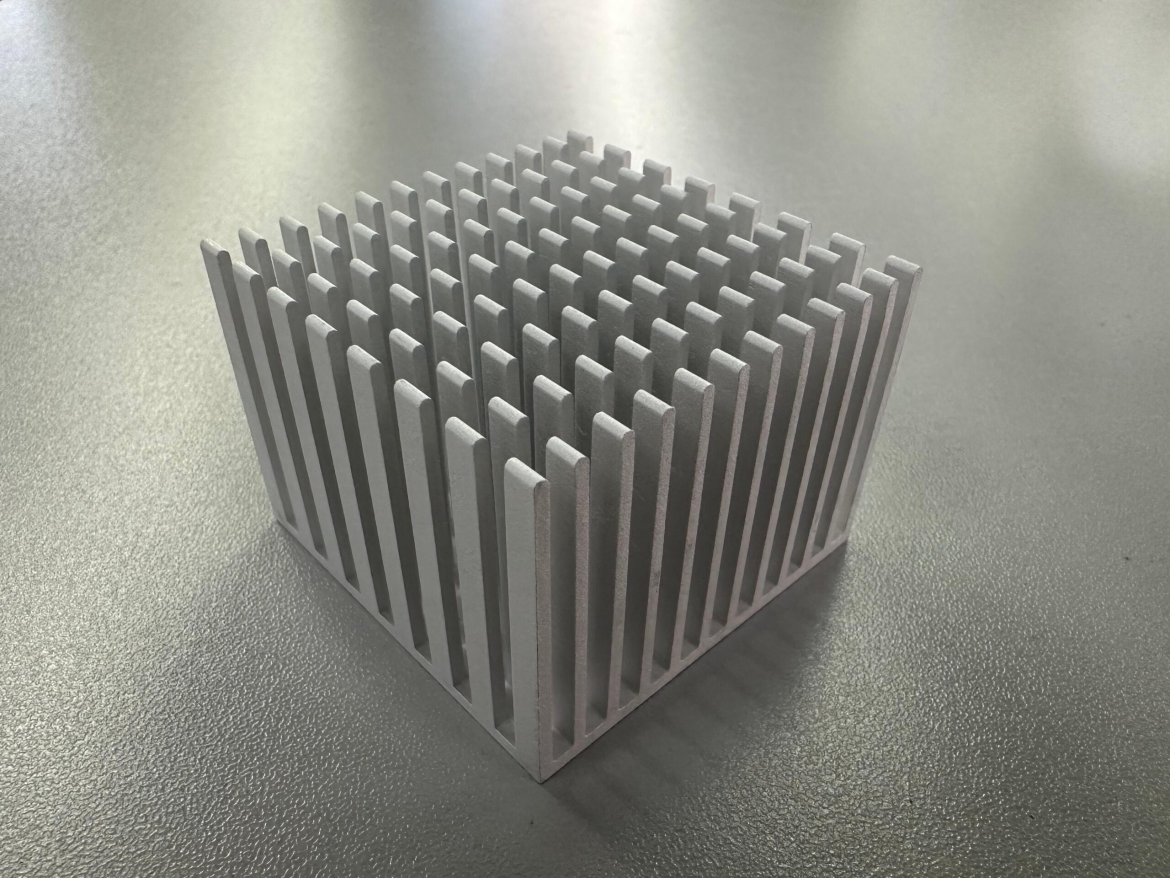

In many industrial and commercial electronics, aluminum extrusion has become a dependable method for producing stable cooling components. An extruded heat sink created through this process is formed by forcing heated aluminum through a die so it can develop a continuous profile with precise fin structures. These fins are essential for guiding airflow, distributing heat, and maintaining consistent operating temperatures. Because companies like Dingmetal often work with procurement teams and R&D engineers, they emphasize how geometry, thickness, and fin spacing influence the overall thermal path. When an extruded heatsink is selected for compact modules or control systems, engineers tend to evaluate how extrusion-formed aluminum balances strength, weight, and thermal conductivity. This balance allows the heat sink to integrate smoothly into device layouts without interrupting mechanical arrangements or electrical connections.

Structural Features of Extruded Heat Sinks That Impact Performance

The performance of an extruded heat sink is shaped not only by its material but also by the structural options available through extrusion. This includes straight fins, flared fins, dense fin arrays, and variations that support both natural and forced convection. For industries dealing with automation, communication hardware, and temperature-sensitive components, the consistency of these shapes is essential. When working with Dingmetal, customers often analyze how different extrusion profiles distribute heat across the base and fins in real usage conditions. Since an extruded heatsink provides predictable conduction paths, it helps reduce temperature fluctuations that could affect long-term reliability. The uniformity provided by the extrusion process also allows teams to plan around heat flow without relying on overly complex cooling systems. This combination of structural stability and thermal efficiency makes aluminum extrusion a suitable approach for designs requiring repeatability and manageable production cycles.

Application Scenarios in Electronic Device Environments

Electronic devices in diverse fields rely on stable heat management, and an extruded heat sink often becomes a practical option for such tasks. It is frequently applied in LED lighting modules, power converters, industrial control equipment, and signal processing boards. These applications benefit from the straightforward installation and durable thermal performance that extruded profiles offer. When Dingmetal supports clients in hardware and module development, they focus on matching extrusion geometries to realistic heat loads rather than relying on theoretical conditions. This ensures the chosen extruded heatsink fits within enclosure limitations and aligns with mechanical components such as mounting plates, PCBs, and airflow passages. Aluminum extrusion also makes scaling easier; when projects grow or require additional capacity, the same profile can be adapted or lengthened without redesigning the entire cooling system. Because of this adaptability, industries with evolving product lines consider extrusion-based heat sinks a reliable foundation for long-term planning.

Conclusion: Why Aluminum Extrusion Supports Reliable Cooling Strategies

When evaluating cooling solutions for electronics, understanding the value behind aluminum extrusion helps teams make informed decisions. An extruded heat sink offers balanced thermal performance, predictable geometry, and compatibility with a wide range of electronic assemblies. Through their experience, Dingmetal supports engineers and procurement specialists who need dependable options that integrate well with both mechanical and thermal requirements. Since an extruded heatsink is produced through a controlled and repeatable process, it remains suitable for devices that require consistent heat diffusion across extended operating periods. These qualities show why aluminum extrusion continues to serve as a practical approach for companies seeking steady cooling performance without introducing unnecessary design challenges.