HUAHUA CNC stands out in the woodworking industry with its advanced automatic edge banding machine. Designed for efficiency and quality, this machine incorporates innovative features that greatly enhance the edge banding process, ensuring professionals achieve exceptional results.

Well Pre-mill, Half Done

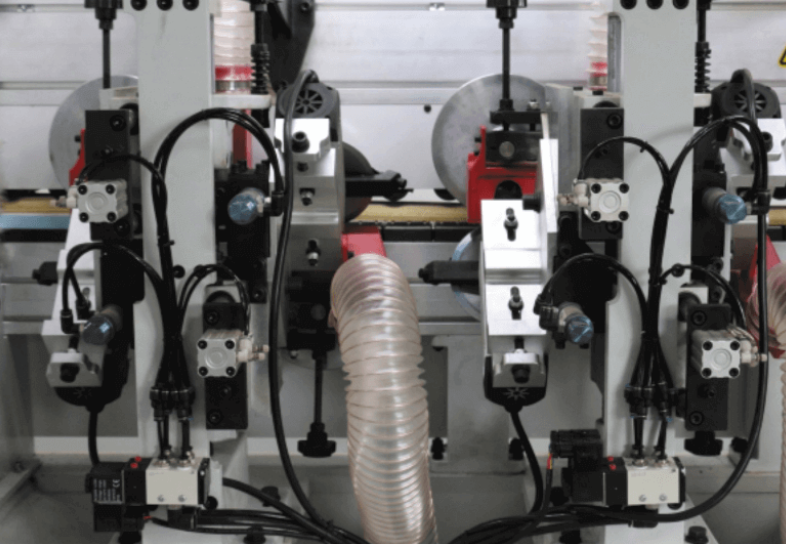

One of the key features of HUAHUA CNC’s automatic edge banding machine is its pre-milling unit. By grinding the edges of panels at the beginning of the process, this unit prepares the surface for optimal adhesion of the banding tape. This crucial step significantly improves the bonding strength, allowing for a smoother, more durable finish. The concept of “well pre-mill, half done” emphasizes how this initial preparation can streamline the entire edge banding process, resulting in high-quality outcomes.

Water-Proof PUR Glue for Enhanced Durability

Another standout feature of the HUAHUA CNC edge banders is the use of water-proof PUR (polyurethane resin) glue in the gluing device. This advanced adhesive is designed to be both water- and damp-proof, providing superior protection against potential damage to wood panels. The use of PUR glue not only enhances the durability of the banded edges but also ensures that the finished product can withstand varying environmental conditions, making it ideal for both indoor and outdoor applications.

Conclusion

In conclusion, HUAHUA CNC’s automatic edge banding machine offers significant advantages for woodworking professionals. With its well pre-milling feature and the use of water-proof PUR glue, these edge banders ensure high-quality, durable finishes that stand the test of time. Investing in HUAHUA CNC technology means choosing reliability and excellence in every woodworking project.